- Polyvinyl Alcohol (PVA)

- Modified Polyvinyl Alcohol PVOH (PVC Grade)

- Modified Polyvinyl Alcohol PVOH(Water Soluble Film Grade)

- PVA Fiber

- VAE Emulsion

- Redispersible Polymer Powder

- Polyvinyl Butyral PVB

- Other Products

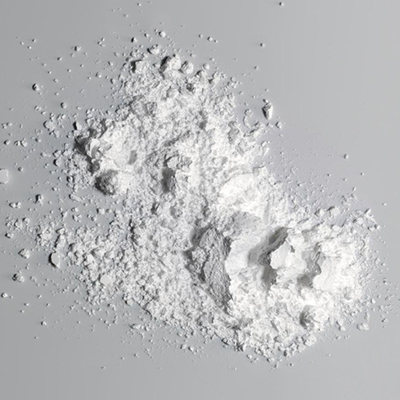

Polyvinyl Butyral PVB Resin

ANHUI LIWEI CHEMICAL CO.,LIMITED

|

Item |

Specifications |

|

Apperance |

White or yellowish powder |

|

PH |

5.0~9.0 |

|

Bulk Density,g/L |

300~600 |

|

Solid Content,% |

≥98.0 |

|

Burning residue,% |

≤13 |

|

Mean particle size D50,μm |

≤100 |

|

Drawing length,Mpa |

≥6.0 |

|

Elongation at break,% |

≥200 |

| Packing | In 25KG triple paper plastic composite bag or as per customer’s requirement. |

|---|---|

| Storage | Store under 30℃ and moisture-proof environment. |

| Shipping | Not regulated as dangerous goods. |

| Liwei PVA is one of the top 10 PVA factories and the top 100 strongest enterprises in anhui province.In 2010,Liwei PVA is evaluated as advanced and high technical company. We mainly deals in polyvinyl alcohol,PVA,PVA fiber and raw materials for producing PVA like vinyl acetate,calcium carbide. |

| For samples, pricing, or more information, please call us at 0086-25-52397803 or mail to info@china-pva.net or fill out the following form. We will respond to you as soon as possible. |

Tel: 0086-25-52397803

E-mail: info@china-pva.net

| Health Hazards | FIRST AID | |

| Inhalation | According to the material form, it is not the normal way of contacting. | Move victim into fresh air. If breathing is difficult, give oxygen and consult a physician immediately. |

| Skin | No harm in general situation. | No harm in general situation. First aid is not needed. |

| Eyes | This product may cause temporary discomfort following direct contact with the eye. | Rinse thoroughly with plenty of water for at least 15 minutes and consult a physician if feel uncomfortable. |

| Ingestion | Accidental ingestion of the product may be harmful to the health of the individual. | Never give anything by mouth to an unconscious person. Call a physician immediately. |

Stability and Reactivity

| Reactivity | Contact with incompatible substances can cause decomposition or other chemical reactions. |

|---|---|

| Chemical stability | Stable under proper operation and storage conditions. |

| Possibility of hazardous reactions | Under normal conditions of storage and use, hazardous reactions will not occur. |

| Conditions to avoid | Incompatible materials, heat, flame and spark. |

| Incompatible materials | Avoid contact with oxidants, acids, alkalis. |

| Hazardous decomposition products | Under normal conditions of storage and use, hazardous decomposition products should not be produced. |

| Safety Phrases | None | ||

|---|---|---|---|

| RIDADR | None | ||

| WGK Germany | None | ||

| Packaging Group | None | ||

| Hazard Class | None | ||

| SYMPTOMS | PREVENTION | FIRST AID | |

| Inhalation | None | None | None |

| Skin | None | None | None |

| Eyes | None | None | None |

| Ingestion | None | None | None |

Polyvinyl butyral resin is a solvent-based resin synthesized from polyvinyl alcohol (PVA) and butyraldehyde in an acetal reaction under the action of a catalyst.PVB resins have a range of superior physical and chemical properties, including high transparency, elasticity, toughness, alkali resistance, oil resistance, flexibility, low-temperature impact resistance, etc. In addition, PVB resins have good adhesion to metals, ceramics, plastics, leather, and wood and exhibit good adhesion to other resins (e.g., epoxy resins, phenolic resins, etc.). In addition, PVB resins have good adhesion to metals, ceramics, plastics, leatherwood, etc., and good compatibility with other resins (e.g., epoxy resins, phenolic resins, etc.)

Safety glass manufacturing: PVB resin is an interlayer material used in the manufacture

of safety glass for automobiles and buildings. When glass is impacted, PVB film prevents

glass fragments from flying and maintains the integrity of the glass, increasing

safety.

Coatings and Inks: PVB resins are used as components in primers, baking paints, wood

finishes, and printing inks, providing excellent adhesion and weathering

resistance.

Electronics & Electrical: PVB resins can be used as binders for electronic ceramics and

printed circuit boards, as well as modifiers for hot melt adhesives to improve product

stability and reliability.

Textile processing: PVB resin can be used to waterproof textiles, providing excellent

waterproofing and anti-pollution properties. It creates strong adhesion with various

fiber materials, allowing textiles to maintain their original softness and

breathability.

Other adhesive applications: PVB resin can also be used as an adhesive between metal and

metal, metal and plastic, providing good adhesion and weather resistance.

Ceramic powder processing: PVB resin can quickly dissolve in most polar and non-polar

solvents due to its special particle porosity and surface properties, making ceramic

powder obtain good strength and softness for processing and molding.

Raw material preparation: After specific quality checks and pretreatment of the two raw

materials, polyvinyl alcohol (PVA) and butyraldehyde, add catalysts, and stabilizers to

promote and control the acetalization reaction.

Dissolution and filtration: the raw materials and additives are mixed and gradually

converted to liquid form under heating conditions. The solution is then passed through a

filtration unit that removes impurities and solid particles to ensure the purity of the

resin.

Degassing and cooling: The filtered resin solution is degassed to remove air bubbles and

excess water. The degassed resin solution is then passed through a cooling unit and

cooled to a suitable temperature for subsequent processing and molding.

Extrusion & Drawing: The cooled resin solution is extruded and stretched to the required

size and thickness using a drawing machine to form the PVB film.

Curing & Cutting: The drawn PVB film is cured by high temperature and pressure to

cross-link the resin molecules in the solid state, increasing the strength and

durability of the film. The cured PVB film is then cut by cutting machines to the

required size for subsequent use.

Packaging: PVB resins should be packaged in well-sealed packaging materials that are

shielded from sunlight, such as ziplock bags or drums, to prevent the ingress of air,

moisture, and other contaminants and damage from ultraviolet rays in sunlight.

Storage: PVB resin should be stored in an environment with stable temperature and

humidity, and the storage area should be kept clean to avoid dust, impurities, and other

contaminants from entering the package.

PEnsure that the operating area has good ventilation conditions and avoid prolonged

contact with resin or inhalation of dust generated by it to reduce irritation to the

respiratory tract and skin.

When handling PVB resin, appropriate personal protective equipment, such as protective

glasses, protective gloves, and respirators, should be worn to prevent direct contact

with the resin with the skin and eyes and to reduce the risk of inhaling resin dust.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.