Agrochemical PVA Water Soluble Film

ANHUI LIWEI CHEMICAL CO.,LIMITED

[Introduction]

Polyvinyl alcohol (PVA) film's physical and chemical properties make it an ideal choice for pesticide packaging. It is water-soluble, has high tensile strength, is puncture-resistant, and can withstand organic solvents. This film is biodegradable and highly water-soluble, leaving no harmful residues after dissolution. Compared to traditional packaging, this significantly reduces plastic waste and environmental pollution. Furthermore, the water solubility of PVA film allows for safer pesticide disposal. Users can directly add the packaged product to water without contact with harmful substances. Additionally, PVA packaging uses pre-measured, single-use packaging, ensuring accurate measurement and minimizing waste.

Applications

From high-concentration formulations for backpack sprayers to convenient small packages for home gardening and plant nutrition, LIWEI's solutions meet the needs of a wide range of agrochemical applications. We also offer a complete range of PVA bags specifically designed for packaging agrochemicals, including:

✓ Insecticide powder

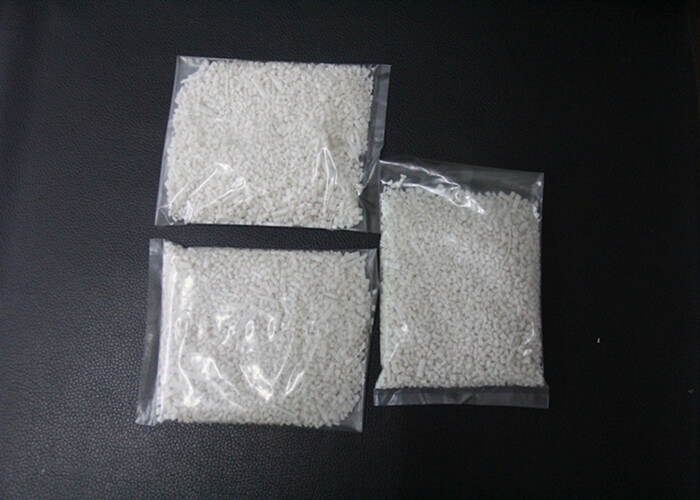

✓ Insecticide granules

✓ Effervescent insecticide tablets

✓ Concentrated liquid active ingredients

✓ Agricultural chemical gels

✓ Herbicides

✓ Fertilizers

✓ Miscible oils

Manufacturing Process

In producing polyvinyl alcohol (PVA) films for agricultural chemicals, we typically use melt extrusion. This efficient process includes the following key steps:

◉ Raw Material Selection: We first select carefully chosen polyvinyl alcohol, along with specific film-forming agents and plasticizers, such as polyvinyl butyral (PVB) or polyvinylpyrrolidone (PVP). The specific ratio depends on the desired film properties.

◉ Mixing and Melting: These materials are mixed and melted at a specific temperature to form a homogeneous mixture.

◉ Extrusion: The molten mixture is extruded through a die to form a uniform film.

◉ Cooling and Post-Processing: After cooling, the film undergoes post-processing. It is then made into bags of specific sizes or rolled into rolls.

◉ Quality Assurance: We conduct rigorous quality checks on each batch of products to ensure they meet our standards for thickness, water solubility, tensile strength, and folding endurance.

◉ Packaging: Finally, we carefully wrap the film to protect it from damage during transportation and storage.